Plasmid Construction: From DNA Design to Purified Plasmid DNA Solutions

|

|

Time to read 1 min

|

|

Time to read 1 min

Synthesis of DNA fragments

Cloning technology to assemble fragments

Purification technologies.

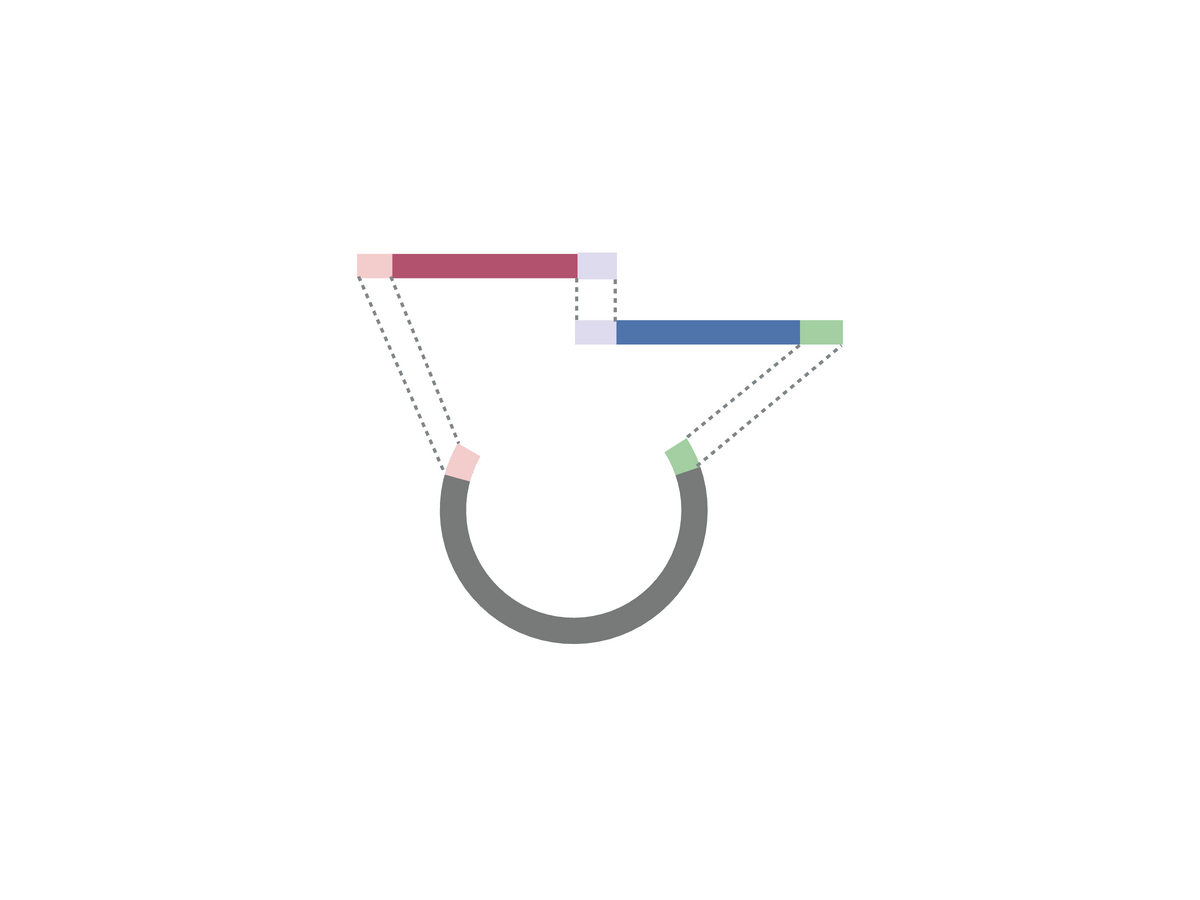

Plasmid construction begins with a computer file containing the DNA sequence to be built—the blueprint of the plasmid. The design is divided into smaller fragments that can be generated by amplifying existing genetic material with PCR or by ordering synthetic DNA through chemical synthesis. Once the DNA fragments are ready, the plasmid construction process continues with their assembly using methods such as Gibson Assembly or Golden Gate cloning. The newly assembled plasmid is then introduced into bacteria, where cells that successfully take up the construct form colonies on selective media. Finally, several colonies are sequenced to verify that the assembled plasmid matches the digital design, ensuring accuracy and reliability in plasmid construction.

Once a positive colony has been identified and sequence-verified, it is expanded into a bacterial culture to produce the biomass required for plasmid purification. Depending on the scale of the culture, different preparation methods are used to isolate plasmid DNA:

Miniprep: ~5 mL of culture yields a few micrograms of DNA, suitable for quick analytical experiments.

Midiprep: ~50 mL cultures provide tens to hundreds of micrograms, often used for cloning and small-scale transfections.

Maxiprep: ~500 mL cultures yield milligram quantities, sufficient for most research applications.

Gigaprep: multi-liter cultures generate tens of milligrams, ideal for large studies or preclinical work.

The purification process begins by separating the bacterial cells from the growth medium, followed by cell lysis to release plasmid DNA. The lysate then undergoes a series of precipitation and chromatography steps to remove proteins, genomic DNA, and endotoxins. Finally, the plasmid DNA is eluted and resuspended in buffer, yielding a concentrated plasmid solution.

Plasmid preparations are available in different quality grades, depending on the downstream application:

Research-grade (standard or low endotoxin) for routine lab use

Endotoxin-free plasmids for sensitive applications such as mammalian transfection

Clinical-grade (cGMP) plasmids manufactured under strict regulatory standards for therapeutic development